Boeing 737 MAX Drives Certification Reform

One series of events that impacted the U.S. transportation industry are the two Boeing 737 MAX accidents that occurred in the later half of 2018 and the first half of 2019. During my Management of Production and Operations course, there were several students that chose to focus their final research presentations about the

two crashes that claimed 346 lives and destroyed two Boeing 737 MAX airframes (Picheta, 2019).

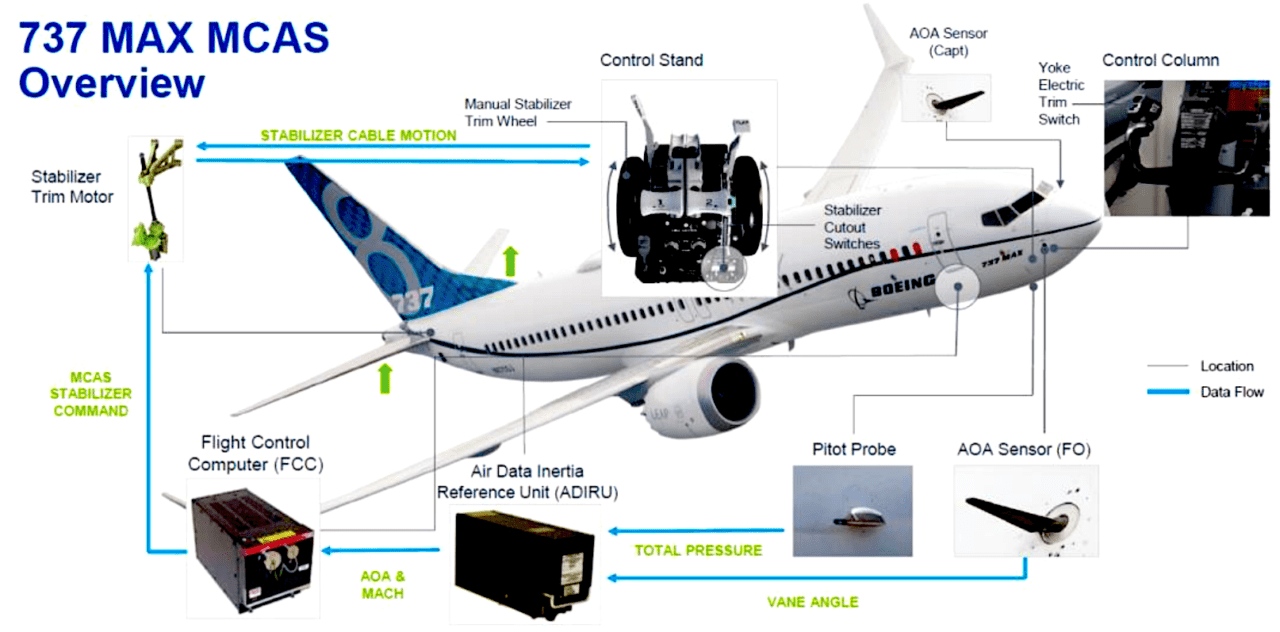

Investigations determined that the maneuvering characteristics augmentation system (MCAS) was not an adequate design due to lack of redundancy, poor software programing, and a sensor system that is prone to failure (Demirci, 2022).

This highlighted a failure in the monitoring and certification of commercial airline products by the Federal Aviation Administration (FAA). The FAA had delegated up to 96 percent of certification processes to Boeing, which started as far back as 2005 (Herkert et al., 2020). Positive change was manifest in certification reform efforts by the FAA. In the last two years, the FAA has delegated less responsibility to manufactures, provides more oversight, conducts more thorough reviews of aircraft system operations, and utilizes independent safety experts for certification projects (Federal Aviation Administration, n.d.).

While the loss of life in these two aircraft mishaps is tragic, the event caused positive change in the FAA’s certification process, which will help prevent future mishaps from occurring.

Resources:

Demirci, S. (2022). The requirements for automation systems based on Boeing 737 MAX crashes. Aircraft Engineering and Aerospace Technology, 94(2), 140-153. https://doi.org/10.1108/AEAT-03-2021-0069

Federal Aviation Administration. (n.d.). Aircraft certification: Certification reform efforts. Retrieved August 6, 2023, from https://www.faa.gov/aircraft/air_cert/airworthiness_certification/certification_reform

Herkert, J., Borenstein, J., & Miller, K. (2020). The Boeing 737 MAX: Lessons for Engineering Ethics. Science and Engineering Ethics, 26(6), 2957-2974. https://doi.org/10.1007/s11948-020-00252-y

Picheta, R. (2019, March 11). Ethiopian Airlines crash is second disaster involving Boeing 737 MAX 8 in months. CNN. https://www.cnn.com/2019/03/10/africa/ethiopian-airlines-crash-boeing-max-8-intl/index.html